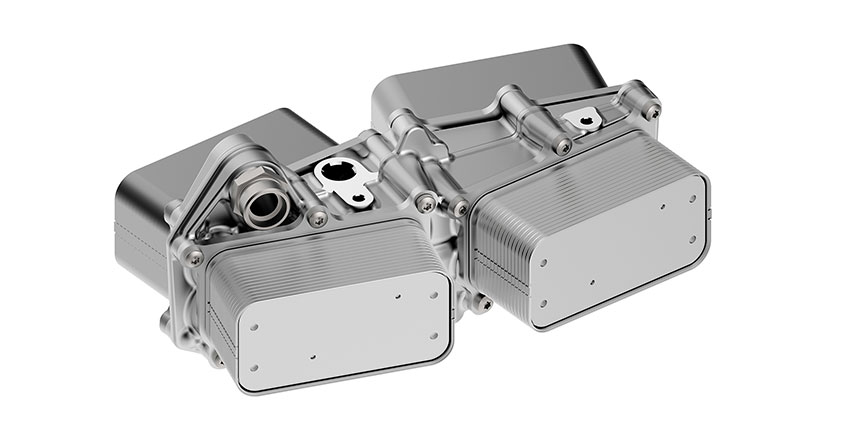

- New e-axle cooler for the Chinese smart electric vehicles manufacturer

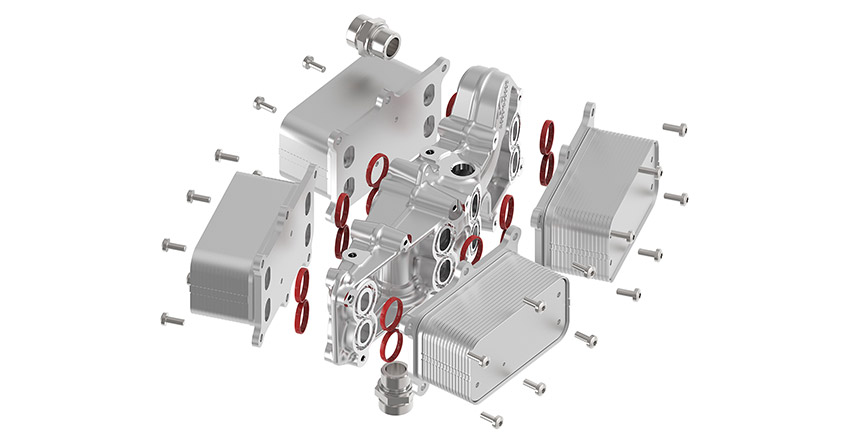

- Optimal thermal behaviour through water-cooled vacuum brazed aluminium technology

- Recognition of the UFI’s advanced engineering and customer relations.

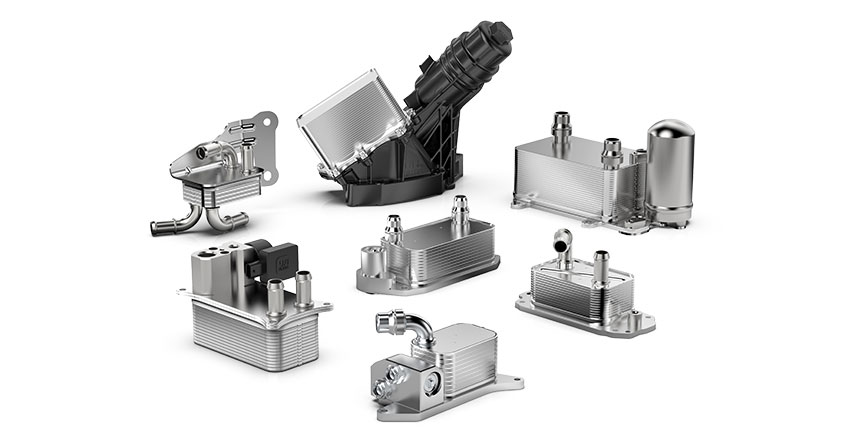

UFI Filters has been pioneering products in thermal management since 2010 and is now one of the industry leaders in an area of high growth. Testimony of this is the latest project awarded by NIO to the UFI Group for the e-axle cooler of a new upcoming Battery Electric Vehicle (BEV).

The e-axle is a core part of BEVs. It works by integrating an e-motor, transmission and power electronics into a compact, modular package that sits between a vehicle’s wheels. As a key element of a BEV, it is essential that the e-axle operates within an optimal range of temperature. UFI Filters technology in water-cooled vacuum brazed aluminium, plays a key role in maintaining the best thermal conditions.

The project has been awarded to UFI in recognition of the company’s advanced engineering and customer relations. For UFI, it represents the beginning of a partnership with a multinational smart vehicle manufacturer headquartered in Shanghai, with branches and R&D departments all around the world. NIO is not just a vehicle manufacturer, it also embodies a new way of conceiving mobility, which is centred on sustainability and the creation of a community of users.

NIO Inc. is a pioneer and leading company in the premium smart electric vehicle market. Founded in November 2014, NIO’s mission is to shape a joyful lifestyle. NIO aims to build a community that starts with smart electric vehicles, in order to share joy and grow together with users. NIO designs, develops, jointly manufactures and sells premium smart electric vehicles and is driving innovations in next-generation technologies in autonomous driving, digital technologies, electric powertrains and batteries. NIO differentiates itself through its continuous technological breakthroughs and innovations, such as its industry-leading battery swapping technologies, Battery as a Service, or BaaS, as well as its proprietary autonomous driving technologies and Autonomous Driving as a Service, or ADaaS. NIO’s product portfolio consists of the ES8, a six-seater smart electric flagship SUV, the ES7 (or the EL7), a mid-large five-seater smart electric SUV, the ES6, a five-seater all-round smart electric SUV, the EC7, a five-seater smart electric flagship coupe SUV, the EC6, a five-seater smart electric coupe SUV, the ET7, a smart electric flagship sedan, and the ET5, a mid-size smart electric vehicle.

Rinaldo Facchini, CEO UFI Filters Group, comments: “Being chosen by one of the leading manufacturers of smart electric vehicles makes us particularly proud. This demonstrates we are paving the way towards 360° mobility. Starting with our know-how gained from the traditional engine, we have been able to develop technologies for vehicles powered by new energies, all thanks to the reactivity and industrial footprint of our Group. The new thermal management business unit and dedicated production sites are therefore able to meet the growing demand for alternative technological innovations.”